लकड़ी और प्लास्टिक से बने मिश्रित पदार्थ (डब्ल्यूपीसी) लकड़ी और प्लास्टिक का संयोजन हैं, जो पारंपरिक लकड़ी के उत्पादों की तुलना में कई लाभ प्रदान करते हैं। डब्ल्यूपीसी अधिक टिकाऊ होते हैं, कम रखरखाव की आवश्यकता होती है और पारंपरिक लकड़ी के उत्पादों की तुलना में अधिक किफायती होते हैं। हालांकि, डब्ल्यूपीसी के अधिकतम लाभ प्राप्त करने के लिए, निर्माण प्रक्रिया के दौरान प्रसंस्करण सहायक पदार्थों का उपयोग करना महत्वपूर्ण है।

डब्ल्यूपीसी उत्पादन में उपयोग किए जाने वाले सबसे आम प्रसंस्करण सहायक पदार्थों में से एक स्नेहक है।स्नेहकलकड़ी और प्लास्टिक घटकों के बीच घर्षण को कम करने में मदद करता है, जिससे उत्पादन प्रक्रिया अधिक सुचारू और कुशल हो जाती है। इसके अतिरिक्त,स्नेहकइससे उत्पादन प्रक्रिया के दौरान उत्पन्न होने वाली गर्मी की मात्रा को कम करने में मदद मिल सकती है, जिससे तैयार उत्पाद के मुड़ने या टूटने का खतरा कम हो सकता है। उत्पादन प्रक्रिया के दौरान प्रसंस्करण सहायक उपकरणों का उपयोग करके, निर्माता यह सुनिश्चित कर सकते हैं कि वे अपने वुडपिक्सेल (डब्ल्यूपीसी) से अधिकतम लाभ प्राप्त कर रहे हैं।

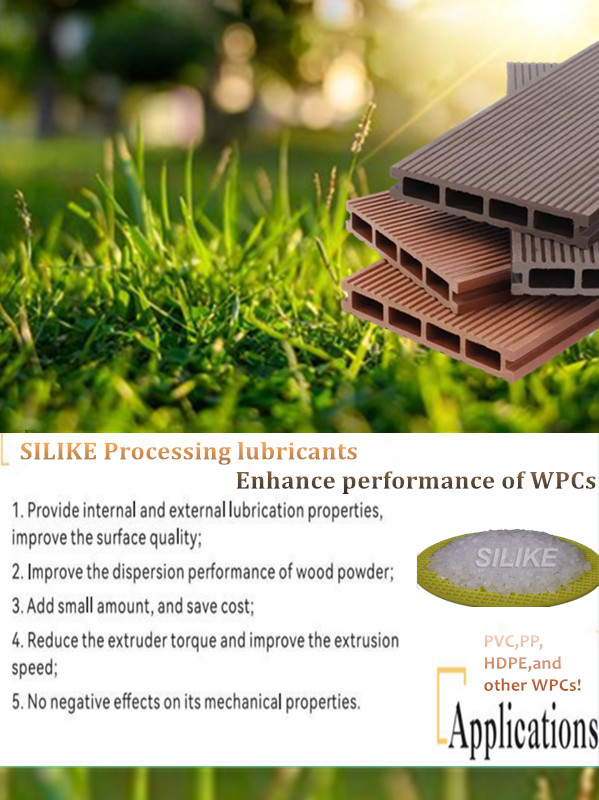

SILIKE प्रोसेसिंग लुब्रिकेंट्स eलकड़ी और प्लास्टिक से बने मिश्रित पदार्थों के प्रदर्शन को बेहतर बनाएं!

SILIKE SILIMER के उत्पाद पॉलीसिलोक्सेन के साथ विशेष समूहों का संयोजन करते हैं। उत्पादन प्रक्रिया के दौरान इन प्रसंस्करण सहायक पदार्थों का उपयोग करके, निर्माता अपने वुड-प्लास्टिक कंपोजिट से अधिकतम लाभ सुनिश्चित कर सकते हैं। इसके अलावा, स्टीयरेट या पीई वैक्स जैसे कार्बनिक योजकों की तुलना में, उत्पादन क्षमता को बढ़ाया जा सकता है। यह एचडीपीई, पीपी और अन्य वुड-प्लास्टिक कंपोजिट के लिए उपयुक्त है।

फ़ायदे:

1. प्रोसेसिंग में सुधार करें, एक्सट्रूडर टॉर्क कम करें

2. आंतरिक और बाहरी घर्षण को कम करें

3. अच्छे यांत्रिक गुणों को बनाए रखें

4. उच्च खरोंच/प्रभाव प्रतिरोध

5. अच्छे जलविरोधी गुण।

6. नमी प्रतिरोधकता में वृद्धि

7. दाग-धब्बों से बचाव

8. बेहतर स्थिरता

पोस्ट करने का समय: 29 मार्च 2023