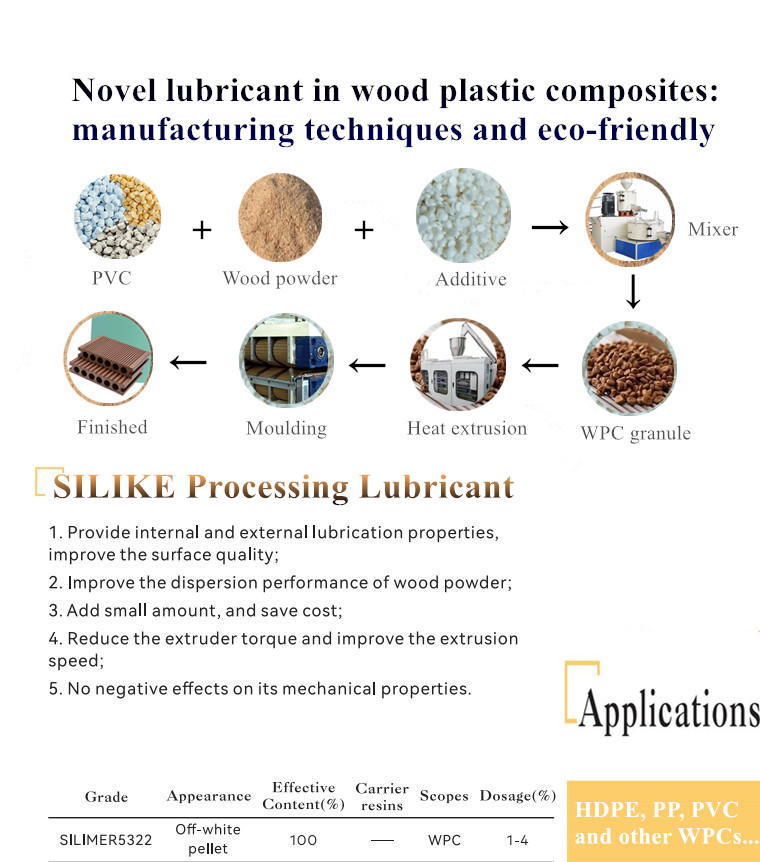

लकड़ी-प्लास्टिक मिश्रित (डब्ल्यूपीसी)प्लास्टिक को मैट्रिक्स और लकड़ी को फिलर के रूप में उपयोग करके बनाया गया एक मिश्रित पदार्थ है, जो योजक चयन के सबसे महत्वपूर्ण क्षेत्रों में से एक है।डब्ल्यूपीसीकपलिंग एजेंट, लुब्रिकेंट और कलरेंट हैं, और केमिकल फोमिंग एजेंट और बायोसाइड भी जल्द ही इस दौड़ में शामिल हो जाएंगे।

आम तौर पर,डब्ल्यूपीसीपॉलीओलेफिन और पीवीसी के लिए मानक स्नेहक जैसे कि एथिलीन बिस्-स्टीरामाइड, जिंक स्टीयरेट, पैराफिन वैक्स और ऑक्सीकृत पीई का उपयोग किया जा सकता है।

क्यों हैंस्नेहकइस्तेमाल किया गया?

स्नेहकलकड़ी के प्लास्टिक कंपोजिट के उत्पादन में इनका उपयोग प्रसंस्करण को बेहतर बनाने और उत्पादन बढ़ाने के लिए किया जाता है। लकड़ी के प्लास्टिक कंपोजिट पदार्थों का एक्सट्रूज़न धीमा और ऊर्जा-खर्चीला हो सकता है, क्योंकि यह पदार्थ शुष्क प्रकृति का होता है। इससे प्रक्रियाएँ अप्रभावी हो सकती हैं, ऊर्जा की बर्बादी हो सकती है और मशीनरी पर टूट-फूट बढ़ सकती है।

सिलिके सिलिमर 5332एक उपन्यास के रूप मेंप्रसंस्करण स्नेहक,यह आपके वुड प्लास्टिक कंपोजिट्स को बेहतर बनाने के लिए नवाचारी शक्ति प्रदान करता है। यह एचडीपीई, पीपी, पीवीसी और अन्य वुड प्लास्टिक कंपोजिट्स के लिए उपयुक्त है, और घरों, निर्माण, सजावट, ऑटोमोटिव और परिवहन क्षेत्रों में व्यापक रूप से उपयोग किया जाता है।

सिलिके सिलिमर 5332एक्सट्रूज़न के दौरान इन्हें सीधे कंपोजिट सामग्रियों में शामिल किया जा सकता है, जिससे निम्नलिखित लाभ देखे जा सकते हैं:

1) प्रसंस्करण में सुधार करें, एक्सट्रूडर टॉर्क को कम करें;

2) आंतरिक और बाहरी घर्षण को कम करना, ऊर्जा खपत को कम करना और उत्पादन क्षमता को बढ़ाना;

3) लकड़ी के पाउडर के साथ अच्छी अनुकूलता रखता है, लकड़ी के प्लास्टिक के अणुओं के बीच के बलों को प्रभावित नहीं करता है।

यह एक मिश्रित यौगिक है और सब्सट्रेट के यांत्रिक गुणों को बनाए रखता है;

4) जलरोधक गुणों में सुधार करना, जल अवशोषण को कम करना;

5) कोई झंझट नहीं, दीर्घकालिक सुगमता;

6) उत्कृष्ट सतह परिष्करण…

पोस्ट करने का समय: 02 नवंबर 2022